weld hardness test procedure|mechanical testing of welds : vendor Procedure of Welding Hardness test. A hardness test is commonly carried out by pressing a particular dimensioned loaded object (indenter) into the surface of the test piece which you are testing, and measuring the impact of the indenter. 11 de jan. de 2024 · 中集车辆致力于成为值得信赖的半挂车及专用车行业世界级领先企业. 企业精神 :. 自强不息、追求卓越. 核心价值观 :. 诚信正直、成就客户、开拓创新、持续改善、合作共赢、结果导向. 使命 :. 为全球道路运输提供可靠、高效的车辆装备,并提供及时、 .

{plog:ftitle_list}

Resultado da 2 dias atrás · Discover millions of assets made by the Roblox community to accelerate any creation task.

All methods of hardness testing are based on the principle of applying a standard load through an indenter and measuring the penetration in terms of diameter/diagonal/depth of indentation. High penetration of an . 1.1 This section covers the bend testing of groove welds in butt joints and the bend testing of surfacing welds. The standard gives the requirements for bend test specimen .

In certain cases, when designing weld procedures, weld zone hardness is often specified not to exceed a certain critical value. There are three main types of harness testing methods for metals, we will be looking at and explaining each . Testing the hardness of a welded joint is well documented in standards like the ISO 9015 and the ISO 15614. These standards describe test loads, number of indents for parent material, heat effected zone (HAZ) and .Procedure of Welding Hardness test. A hardness test is commonly carried out by pressing a particular dimensioned loaded object (indenter) into the surface of the test piece which you are testing, and measuring the impact of the indenter.Here you will find general practical tips on hardness testing as well as useful information on the most common hardness testing applications such as progression measurements (CHD, NHT, RHT), hardness mapping, weld .

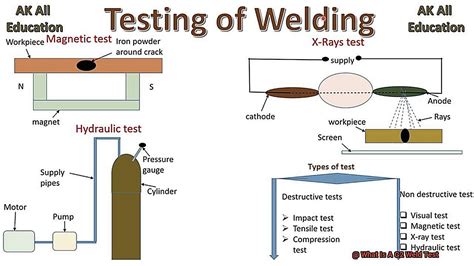

what is a welding test

welding testing methods

A weld hardness test is performed by mechanically pressing a specifically dimensioned object, known as an indenter, onto the weld. Hardness is then determined by measuring the penetration or size of the impression left by the .

Hardness testing assesses a material’s ability to resist permanent deformation at its surface by applying pressure with a harder material. It finds applications across various industries for .Standardized weld sample testing. Testing of weld samples is defined in standards ISO 9015 and ISO 22826. ISO 9015 Part 1 describes hardness testing of arc-welded joints. Part 2 deals with micro hardness testing of welded .

welding joint hardness testing

The preliminary welding procedure specification shall be prepared in accordance with ISO 15609-1 or ISO 15609-2. 5 Welding procedure test The welding and testing of test pieces shall be in accordance with Clauses 6 and 7. The welder or welding operator who undertakes the welding procedure test satisfactorily inThis document outlines the procedure for hardness testing of production weldments in piping. It describes testing the hardness of all pipe joints using Brinell hardness testing on the base material, heat affected zone, and weld. .3.2 Conducting the Test. Positioning the Sample: Secure the material sample in the testing machine.; Selecting the Indenter: Choose the appropriate ball diameter based on the material hardness.; Applying the Load: Gradually apply the specified load using the machine.The load should be maintained for a predetermined dwell time, usually between 10 to 15 seconds.The Vickers hardness testing method offers advantages such as a small indentation size, accurate hardness measurements, and applicability to a wide range of materials. Series measurements or mappings are very often carried out using this met-hod. However, it may not be suitable for very soft or highly textured materials, while alternative .

weld shear test procedure

Welding and material testing is a process of inspecting and checking the results of welding, whether the material has a defect or not, and check the mechanical properties of the joint and the material. . According to the hardness test procedure, the material is subjected to pressure using an indenter type during the hardness test. The Brinell . preparation, test parameters and testing procedures but does not specify the bend radius requirements or accep-tance criteria. 1.2 The base materials may be homogenous, clad or otherwise surfaced, except for hardfacing. 1.3 This standard is applicable to the following, where specified: (1) Qualification of materials, welding personnel and .Figure 3 — Recommended location for taking sections through welds: seam weld 7 Hardness test locations and procedure 7.1 Choice of test Low-force Vickers hardness testing (see 3.1), is recommended for hardness testing of the parent material, the .A hardness test is typically performed by pressing a specifically dimensioned and loaded object (indenter) into the surface of the material you are testing. The hardness is determined by measuring the depth of indenter penetration or by measuring the size of the impression left by an indenter. Hardness tests that measure the depth of .

The qualification of welding procedures is necessary to ensure that the selected welding parameters can produce sound welds. Qualification typically involves a combination of destructive and nondestructive testing. When a particular code, such as AWS D1.1 or ASME Section IX is used, the code will dictate the type and numbers of tests necessary in order [.]Our simple and easy-to-use high-resolution digital camera equipment delivers fast results for weld testing and structure verification. Non-Destructive Testing. . The Vickers hardness test is a versatile hardness test method, used for both macro and micro hardness testing. It has a broad load range, and is suitable for a wide range of . The test is performed by welding a test coupon, which is then subjected to various tests (such as tension, bend, and Charpy impact) to determine the weld’s mechanical properties. If the test results meet the requirements specified in ASME Section IX or AWS D1.1 , then the welding procedure can be qualified for use in manufacturing.

Each hardness test varies by method; however, the procedures all remain relatively similar. A weld hardness test is performed by mechanically pressing a specifically dimensioned object, known as an indenter, onto the weld. Hardness is then determined by measuring the penetration or size of the impression left by the indenter. Hardness testing of weld overlay procedure test as per ISO 15156-2. Hardness testing shall be carried out by the Vickers 10-kg or 5 kg method in accordance with ISO 6507-1 I ASTM E 92. Hardness testing shall additionally be carried out by the Rockwell method in accordance with ISO 6508-1 I ASTM E 18.

weld shear test pdf

Weld Consumable Excel Calculator Download Link Weld Consumable Calculation PPT Free Download For Training . Rockwell Hardness Test: This method assesses the depth of indentation caused by a specific load on the material’s surface. It’s highly versatile and straightforward, making it widely used across industries. .

hardness test in dialysis

Hardness Testing. Hardness testing measures the weld’s resistance to indentation or penetration by using a hardness tester. . What is destructive weld testing? Destructive weld testing is a method used to .Hardness requirements for welds shall be as per the Welding Specification Chart/Non Destructive Examination Specification included in welding contract. Hardness testing shall be carried out by Vickers Hardness Tester during welding procedure qualification and shall be cross sectional.

To ensure that welds are consistent, reliable, and up to industry standards, weld test procedures are utilised. In this blog post, we will delve deep into the intricacies of weld test procedures, emphasising their significance and the various methods employed. Understanding the Importance of Weld Test Procedures

hardness test in industry

ATS is able to test all aspects of weld procedure and performance qualifications by conducting destructive and nondestructive tests to ensure conformance to requirements of applicable codes and standards. . Weld Hardness Testing; Weld Inspections; Weld Inspections Services; Weld Joint Testing; Weld Notch Toughness Testing; Weld Procedure . Loads of Different Hardness Test Methods. Each hardness testing method has a range of loads that are applicable to the use of the test. Some tests, like the Vickers hardness test, can be used on a macro scale as well as a micro scale. The .Parent Metal Test Method Weld Metal Test Method HAZ Test Method Hardness Survey Production Test Remarks NACE MR0175 - 22 HRC 187 HBW (forging per A105) 197 HBW (fitting per A234) 2015 NACE MR0103 - 2015 not required for P No.l in Sec. IX ASME BPVC with heat treated condition per 13.1.1c

This method of weld testing (often referred to as fracture testing) is handy for figuring out the inside quality of the metal you have utilized. It will make defects such as slag inclusions, degraded fusion, oxidized metal, gas pockets, and burned metal come to light. . Hardness Testing. In weld testing, the term hardness relates to the .

TableofContents ListofFigures ix ListofTables xii 1.Introduction 1 2.RockwellHardnessTest 2 2.1Significanceofthetest 2 2.2Rockwellindentationtestprinciple 2 2 .Our simple and easy-to-use high-resolution digital camera equipment delivers fast results for weld testing and structure verification. Non-Destructive Testing. . When selecting a hardness test method, important considerations include: The type of material to be hardness tested; 2.1 Tensile Test. Tensile properties of the weld joints, namely yield and ultimate strength and ductility (%age elongation and %age reduction in area), can be obtained either in ambient condition or in special environment (low temperature, high temperature, corrosion, etc.) depending upon the requirement of the application using tensile test which is usually . 3. X-Ray Testing. This physical weld testing radiographic method reveals the presence and nature of the internal defects in a sample of the weld, like cracks, blowholes, slag, and improper fusion zones. We keep an x-ray tube on one side of the sample welded plate and an x-ray film specially designed sensitive emulsion on the other side.

Hardness Testing. Hardness testing is a common method used in welding to assess the hardness of welded joints and the surrounding base material. This testing technique provides information about the material’s resistance to indentation or penetration, offering insights into its strength, durability, and suitability for specific applications. 9.

hardness test in pharmaceutical

hardness test in pharmaceutical industry

web1 de fev. de 2020 · Cs-Portable 08:13 还有一些CS Portable的修改版,与原版差别不大。大家可以进qq群710447758, 视频播放量 57940、弹幕量 239、点赞数 1238、投硬币枚数 111、收藏人数 673、转发人数 27, 视频作者 精英船员, 作者简介 编辑个性签名,相关视频:《试玩》——反恐精英便携版(CS portable),【手游cs进化史】从便携版CS到CSSO手机 .

weld hardness test procedure|mechanical testing of welds